Apache

Apache

Apache Helicopters

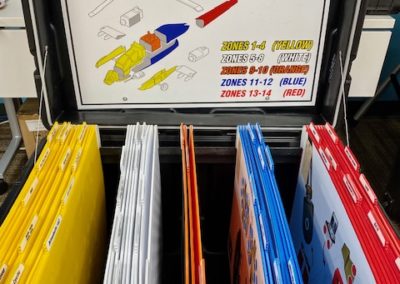

Our kits include both the PMI 1 and 2 phases. The major task required of the maintainers during a PMI 1 or 2, is to put the bolt in the correct patented, pre-designed, cut hole. This is important because of the different lengths of hardware and thread types. If this is not performed correctly the mechanic must restart the same tasks due to damaged hardware or mechanical parts. For Example, the Blast shield has over a hundred and fifty holes of all different lengths. The importance of putting the hardware back into the correct hole is vital and our panels makes this process easier and more efficient. Bolt Byte secures the hardware on boards, and is placed in Pelican boxes, eliminating plastic bags and cardboard. This initiates a solid FOD reduction program for the unit.

Our Work

Testimonials

The results from our test boards far exceeded our expectations. FOD was but one advantage to the boards. Our install time improved, there was not confusion on where anything went and interruptions to workflow did not mean starting over to find where the technician left off. Prior to the boards, we would often take extra hardware, several ship sets, to work a task. The boards allowed us to sort exactly what we needed. No longer do technicians take more than they need and the weight is much less. A big safety concern removed.